-

02-09 2026

Revolutionizing Precision in Automotive Mold Manufacturing

In today’s competitive automotive sector, the demand for world-class automotive parts mold solutions has never been higher. Leading suppliers deliver cutting-edge automotive parts mold systems that combine repeatability, tight tolerances, and robust materials. By harnessing next-generation automotive precision injection mould techniques, manufacturers guarantee consistent quality across high-volume runs. From P20 and H13 steel to S136 and NAK80 cores, every automotive precision injection mould component is engineered for reliability. As OEMs push for slimmer margins of error, the role of a true automotive high precision mold partner becomes indispensable.

-

01-30 2026

Crafting the Modern Home: Precision Plastic Molds Redefine Household Essentials

The global market for household items is witnessing a significant shift, driven by precision manufacturing and material science. At the forefront are companies leveraging advanced plastic injection molded home candlestick designs and intricate plastic molded cookie model kits, transforming everyday objects into examples of reliability and artistry. These products, originating from manufacturing hubs like China, combine meticulous engineering with practical design to meet evolving consumer demands.

-

09-12 2025

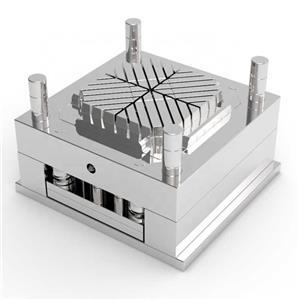

Home Appliances Precision Plastic Injection Mold

Discover our high-precision injection molds engineered for home appliance components, featuring versatile cavity designs, premium mold steels (P20, H13, S136, NAK80, 718), and advanced runner systems for overmolding, double-shot, and multi-color applications.

-

08-04 2025

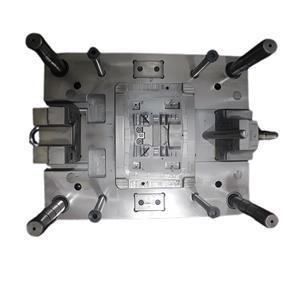

Automotive Precision Plastic Injection Mold

Part name: Automotive Precision Plastic Injection Mold Material: P20,H13,S136,NAK80,718, or customized , etc. Mould type: 1 or 2 Cavity numbers or customized Cavity&Core: P20, 718, NAK80, S136, H13, customized, etc. Mould base: LKM Hot runner: needle nozzle direct on part, hot tip, etc. Cold runner:tunnel gate Tolerance 0.05mm Charactristic: Repeatability- Make consistently good parts Close-tolerance processing- precision is key in automotive parts Secondary operations- all the processes you need under one roof Scalability- the automotive industry is expected to grow Wide material selection- ABS, PP, PVC, PC, PE, PA, POM, and more

-

08-04 2025

Innovative Plastic Injection Molded

Part name: Plastic injection molded two shots part Material: ABS+PC, PC, PA6+30%GF, etc. Mould type: 1 or 2 Cavity numbers Cavity&Core: 1.2344,1.2767, Superplast 400, or customized Mould base: LKM hot runner: needle nozzle direct on part,tunnel gate, hot tip Tolerance 0.05mm

-

06-13 2025

Injection Molded Plastic Needle Tubing

Injection Plastic Needle Tubing: Advanced Manufacturing Solutions for Precision Applications Our injection plastic needle tubing meets the most demanding requirements across medical, laboratory, and industrial sectors. Utilizing high-precision molds with tolerances of 0.05mm, we produce consistent, reliable tubing with customizable material properties.

-

05-14 2025

Rapid Injection Molding Electrical Prototypes

Part name: Electrical Prototype Rapid Injection Mold Material: steel, P20 (1.2311), H13 (1.2344), S136 (1.2083), NAK80 (P21), 718 (1.2738), 420 (1.2083),420 (1.2083) etc. Mould type: Prototype Rapid mold Cavity&Core: steel, P20 (1.2311), H13 (1.2344), S136 (1.2083), NAK80 (P21), 718 (1.2738), 420 (1.2083),420 (1.2083) etc. Mould base: LKM Hot runner: needle nozzle direct on part, hot tip, etc. Cold runner:tunnel gate Tolerance: 0.05mm Charactristic: Cost-effective, Design flexibility, material selection, Consistency and quality, Time and resource savings

-

05-14 2025

Medical Precision Plastic Injection Molds Design

Part name: Medical Precision Plastic Injection Mold Material: steel, 1.1730,1.2344,1.2767, Superplast 400, or customized , etc. Mould type: 1 or 2 Cavity numbers or customized Cavity&Core: P20, 718, NAK80, S136, H13, customized, etc. Mould base: LKM Hot runner: needle nozzle direct on part, hot tip, etc. Cold runner:tunnel gate Tolerance 0.05mm Charactristic: Repeatability- Make consistently good parts Close-tolerance processing- precision is key in automotive parts Secondary operations- all the processes you need under one roof Scalability- the automotive industry is expected to grow Wide material selection- ABS, PP, PVC, PC, PE, PA, POM, and more

-

04-15 2025

Rapid Medical Prototype Mold Injection

Revolutionizing Healthcare: The Power of Medical Prototype Injection Mold Technology In medical device development, medical prototype injection mold systems have become indispensable tools for accelerating innovation. These advanced manufacturing solutions, including medical rapid plastic injection mold processes and Rapid injection medical model techniques, are transforming how life-saving equipment reaches patients faster while maintaining rigorous quality standards.

-

01-22 2025

High Performance Mold Injected Plastic Pipes

High-performance mold-injected plastic pipes represent a significant advancement in piping technology, offering a compelling alternative to traditional materials like steel, copper, and concrete. These pipes, manufactured through a precise injection molding process, boast superior properties that make them ideal for a wide array of applications, from demanding industrial settings to residential plumbing systems. The increasing demand for durable, cost-effective, and environmentally friendly piping solutions has propelled the growth of this sector, making it a crucial area of study for engineers, contractors, and material scientists alike. Understanding their unique characteristics and advantages is crucial for making informed decisions in various construction and infrastructure projects.