High-Performance Polymer Solutions for Banking Systems

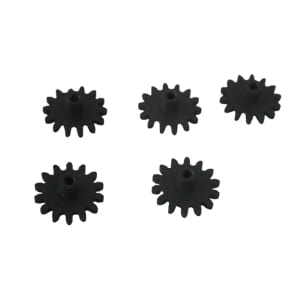

ATM Precision Gears: High-Performance Polymer Solutions for Banking Systems

Technical Specifications

Part Name: ATM Precision Gear

Materials:

ABS+PC (impact-resistant for high-traffic ATMs)

PC (optical clarity for sensor alignment gears)

PA6+30%GF (glass-reinforced for load-bearing components)

Mold Configuration:

1-2 cavity precision molds

Cavity/Core: 1.2344 ESR steel (HRC 50-52) for >500k cycles

Alternative: Superplast 400 for complex geometries

Runner Systems:

Hot runner: Yudo needle nozzle direct gating

Cold runner: Submarine gates for automatic degating

Tolerance: ±0.05mm (achievable through temperature-controlled molding)

Advanced Manufacturing Process

Our ATM precision gears undergo:

Scientific molding with cavity pressure monitoring

100% dimensional inspection via CMM

Run-in testing under simulated ATM conditions

Surface treatment (optional PTFE coating for reduced friction)

7 Key Advantages of Plastic ATM Gears

Noise Reduction Technology

15-20dB quieter than metal gears (tested per ISO 3746)

Vibration-damping polymer structures

Optimized tooth profile reduces meshing noise

Lightweight Engineering

70% weight reduction vs. brass gears

Enables smaller ATM motor systems

Reduces bearing wear by up to 40%

Superior Corrosion Resistance

Withstands humidity up to 95% RH

Resistant to banknote dust and cleaning chemicals

No galvanic corrosion in mixed-material systems

Self-Lubricating Performance

Internally lubricated compounds available

Maintenance-free operation for 10+ years

Special formulations for extreme temperatures (-30°C to 85°C)

Cost Optimization

30-50% lower total cost vs. metal gears

Faster cycle times (typically 25-35 seconds)

Reduced secondary operations

Precision Engineering

AGMA Class 8-9 accuracy

Profile modifications prevent edge loading

Tight concentricity (<0.03mm TIR)

Customization Capabilities

Custom tooth forms for specific torque requirements

EMI shielding options available

Color-coding for service identification

ATM-Specific Design Features

Anti-static compounds prevent dust accumulation

UV-stabilized materials for outdoor ATMs

RFID-compatible material options

Integrated wear indicators

Quality Assurance

Full material traceability

Batch testing for mechanical properties

100% gear run-in testing

PPAP documentation available

Industry Applications

Cash dispensing mechanisms

Card reader drives

Security shutter systems

Touchscreen adjustment gears

Why Our ATM Precision Gears?

ISO 9001:2015 certified production

Rapid prototyping available (72-hour turnaround)

Global technical support network

For your next ATM project, trust our precision gear solutions that combine advanced polymer science with banking-grade reliability. Contact our engineering team today for custom material recommendations and DFM analysis.