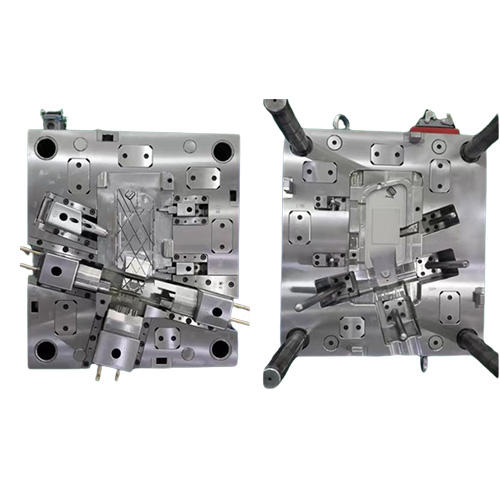

Electrical Precision Plastic Injection Mold

Product origin China

Delivery time as customer requested

Supply capacity 20-40 sets/month

Part name: Electrical Precision Plastic Injection Mold

Material: steel, 1.1730,1.2344,1.2767, Superplast 400, or customized , etc.

Mould type: 1 or 2 Cavity numbers or customized

Cavity&Core: P20, 718, NAK80, S136, H13, customized, etc.

Mould base: LKM

Hot runner: needle nozzle direct on part, hot tip, etc.

Cold runner:tunnel gate

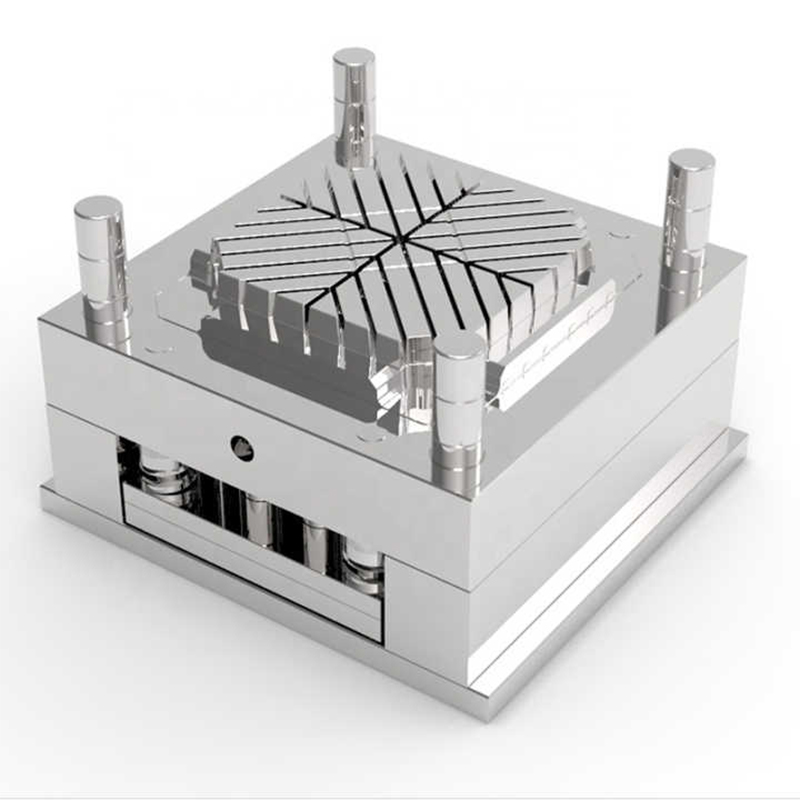

Tolerance 0.05mm

Charactristic:

Repeatability- Make consistently good parts

Close-tolerance processing- precision is key in automotive parts

Secondary operations- all the processes you need under one roof

Scalability- the automotive industry is expected to grow

Wide material selection- ABS, PP, PVC, PC, PE, PA, POM, and more

1. High precision: Electronic precision injection molds have high manufacturing precision, meeting the high requirements of electronic products for dimensions and shapes.

2. High efficiency: Precision injection molds have high production efficiency, enabling fast completion of large-scale production tasks and improving production efficiency.

3. Excellent surface quality: Products manufactured with electronic precision injection molds have smooth surfaces without burrs, meeting the aesthetic requirements of electronic products.

4. High reliability: Precision injection molds are made of high-quality materials and advanced manufacturing processes, ensuring high wear resistance and corrosion resistance, and guaranteeing the service life and stability of the molds.

5. Cost-saving: Electronic precision injection molds enable automated production, reducing labor costs, improving production efficiency, and lowering production costs.

6. Strong versatility: Precision injection molds can produce products with various complex shapes, meeting the diversity and innovation requirements of electronic product designs.

7. Environmental friendly: The materials used in precision injection molds can be recycled, reducing environmental pollution and meeting environmental requirements.

8. Easy maintenance: Precision injection molds are easy to maintain and repair, allowing for timely repair and replacement of damaged parts, and extending the service life of the molds.