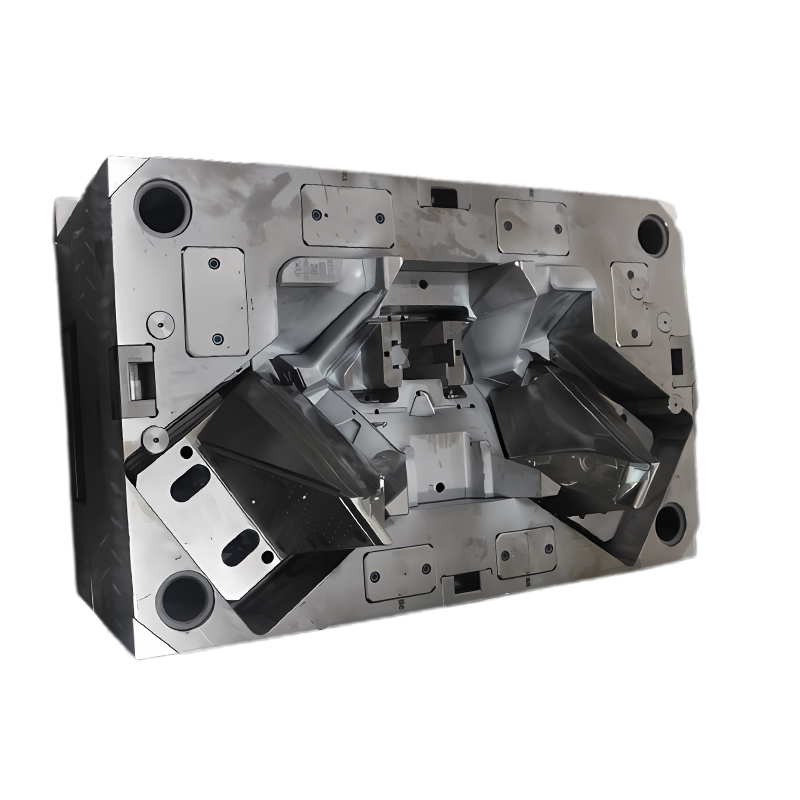

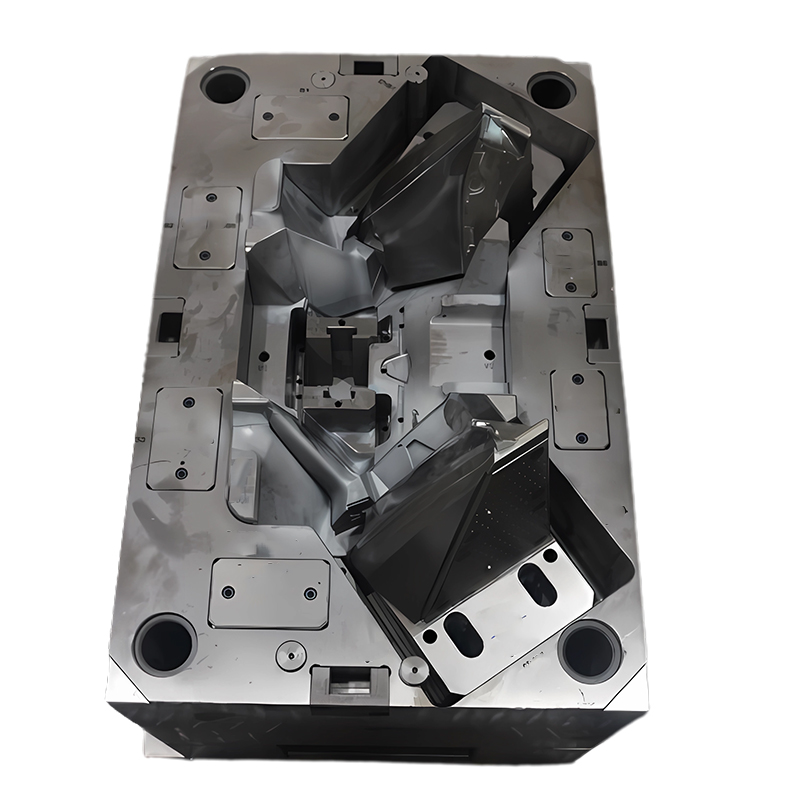

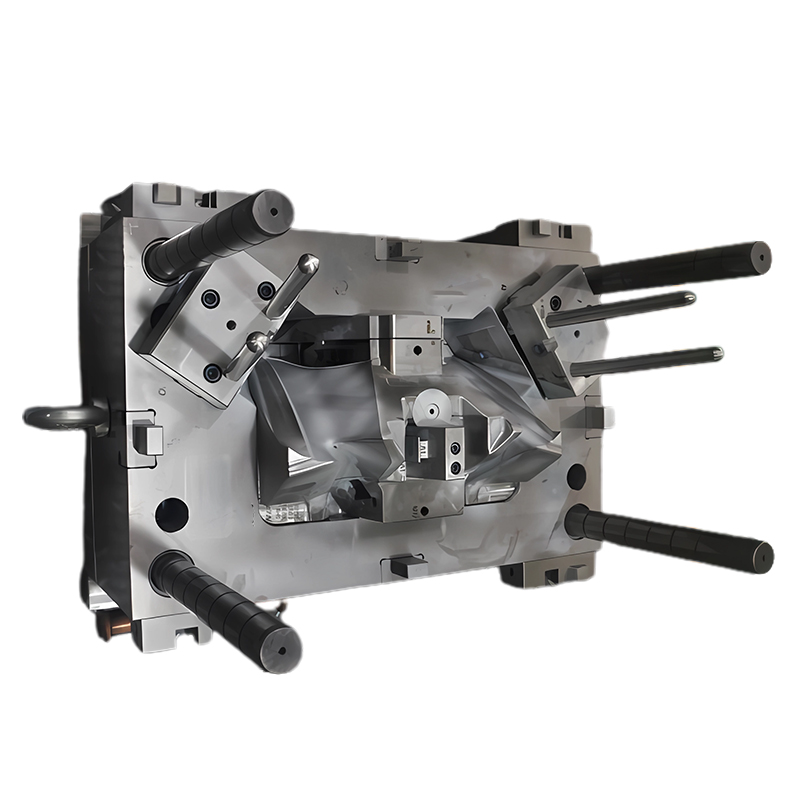

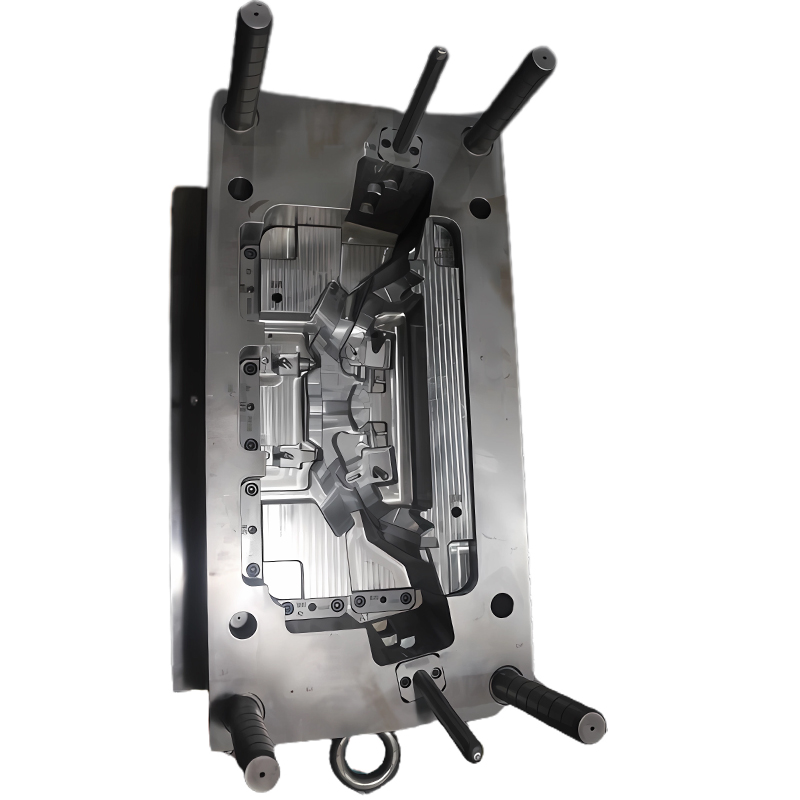

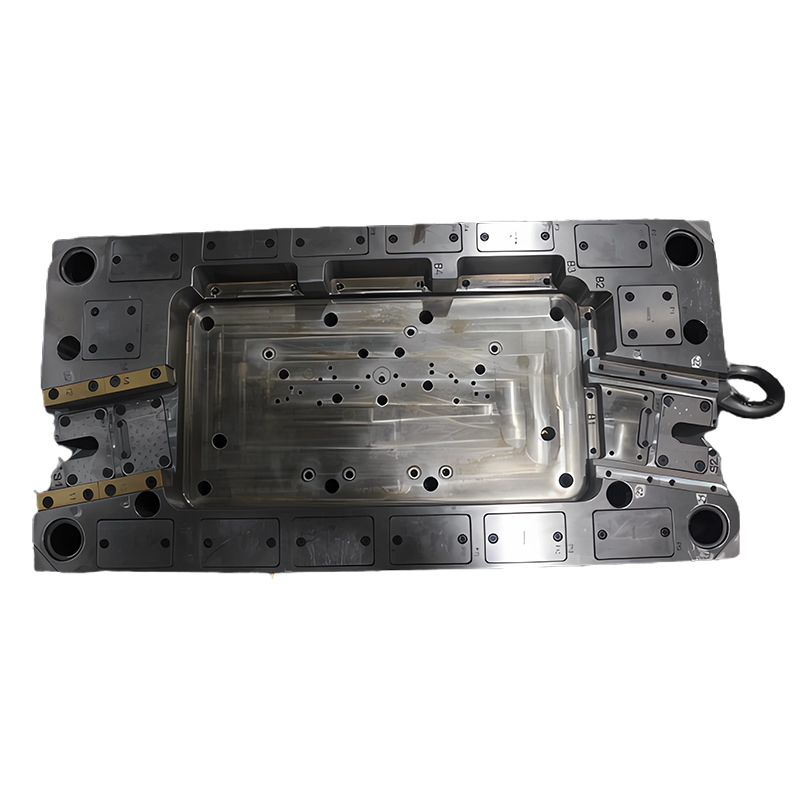

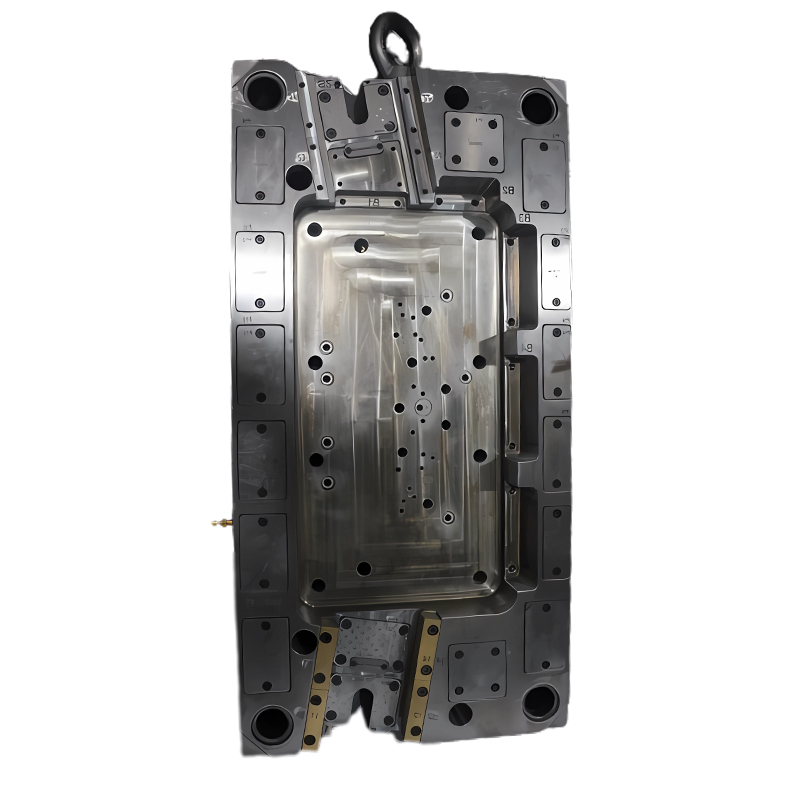

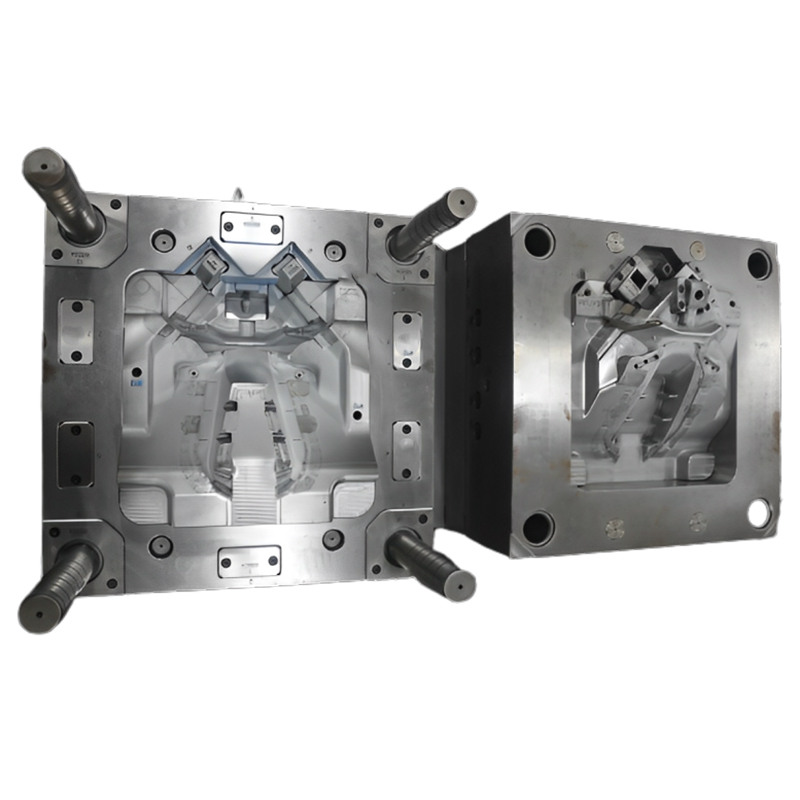

Automotive Precision Plastic Injection Mold

Product origin China

Delivery time as customer requested

Supply capacity 20-40 sets/month

Part name: Automotive Precision Plastic Injection Mold

Material: P20,H13,S136,NAK80,718, or customized , etc.

Mould type: 1 or 2 Cavity numbers or customized

Cavity&Core: P20, 718, NAK80, S136, H13, customized, etc.

Mould base: LKM

Hot runner: needle nozzle direct on part, hot tip, etc.

Cold runner:tunnel gate

Tolerance 0.05mm

Charactristic:

Repeatability- Make consistently good parts

Close-tolerance processing- precision is key in automotive parts

Secondary operations- all the processes you need under one roof

Scalability- the automotive industry is expected to grow

Wide material selection- ABS, PP, PVC, PC, PE, PA, POM, and more

The steel materials used for Automotive Precision Plastic Injection Mold can include:

1. P20: P20 is a low-alloy steel with good toughness and excellent machinability. It is commonly used for medium to large-sized molds, as it offers good wear resistance and high polishability.

2. H13: H13 is a hot work tool steel that is known for its high toughness and heat resistance. It is often used for molds that require high temperature resistance, such as those used for automotive parts that undergo heat during the molding process.

3. S136: S136 is a stainless steel material that is commonly used for precision molds. It offers good corrosion resistance and high polishability, making it suitable for automotive parts that require a high level of precision and surface finish.

4. NAK80: NAK80 is a pre-hardened mold steel that offers good dimensional stability and high polishability. It is often used for molds that require high precision and surface finish, such as those used for automotive interior components.

5. 718: 718 is a high-strength, corrosion-resistant steel that is commonly used for molds that require high durability and long tool life. It is often used for automotive molds that are subjected to high production volumes and demanding operating conditions.

These are just a few examples of the steel materials that can be used for Automotive Precision Plastic Injection Mold. The choice of steel will depend on factors such as the specific requirements of the mold, the type of plastic being injected, and the expected production volume.