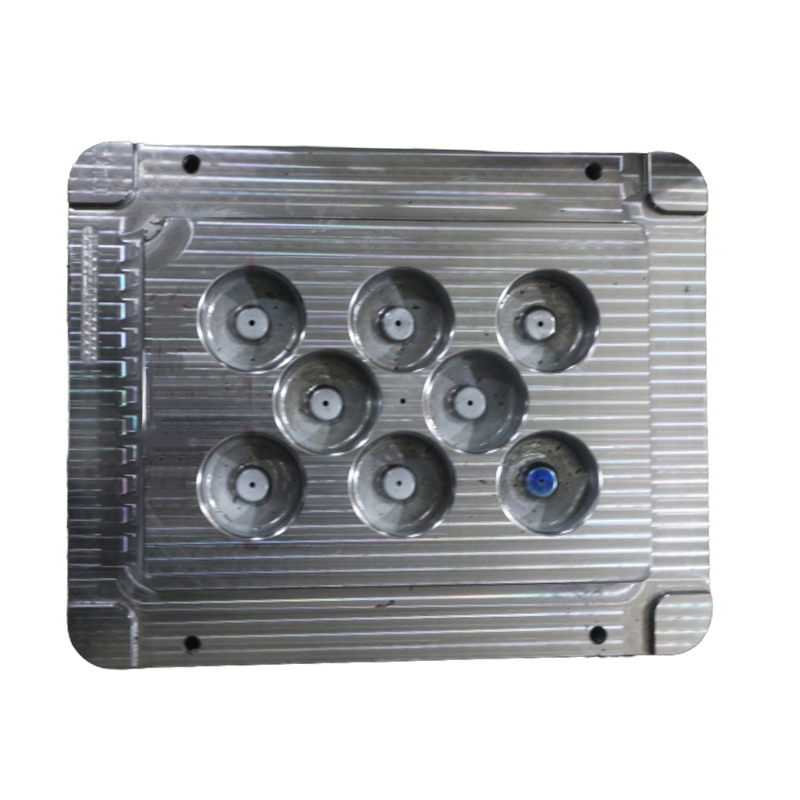

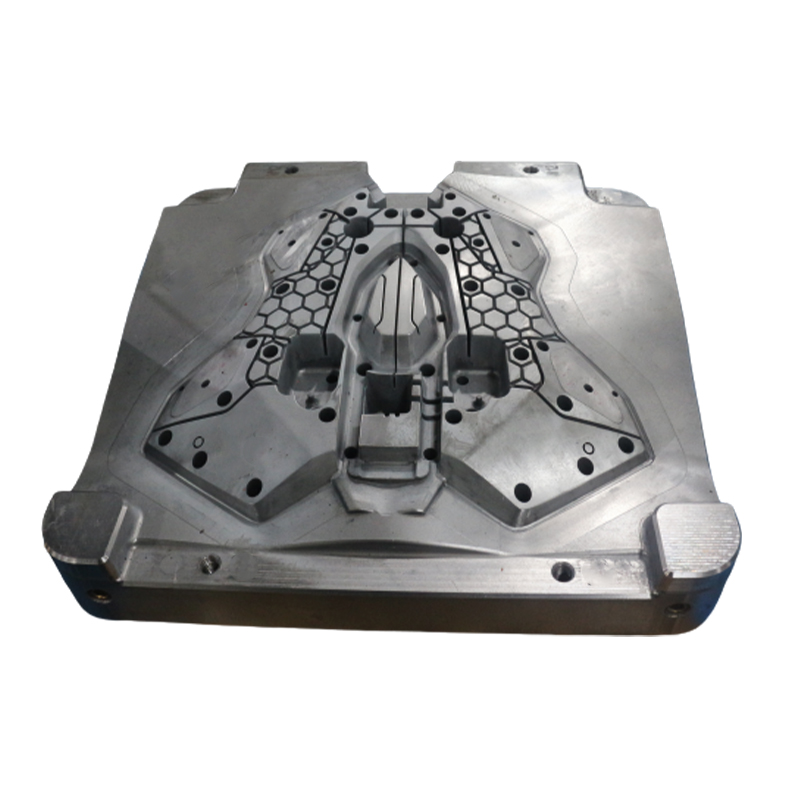

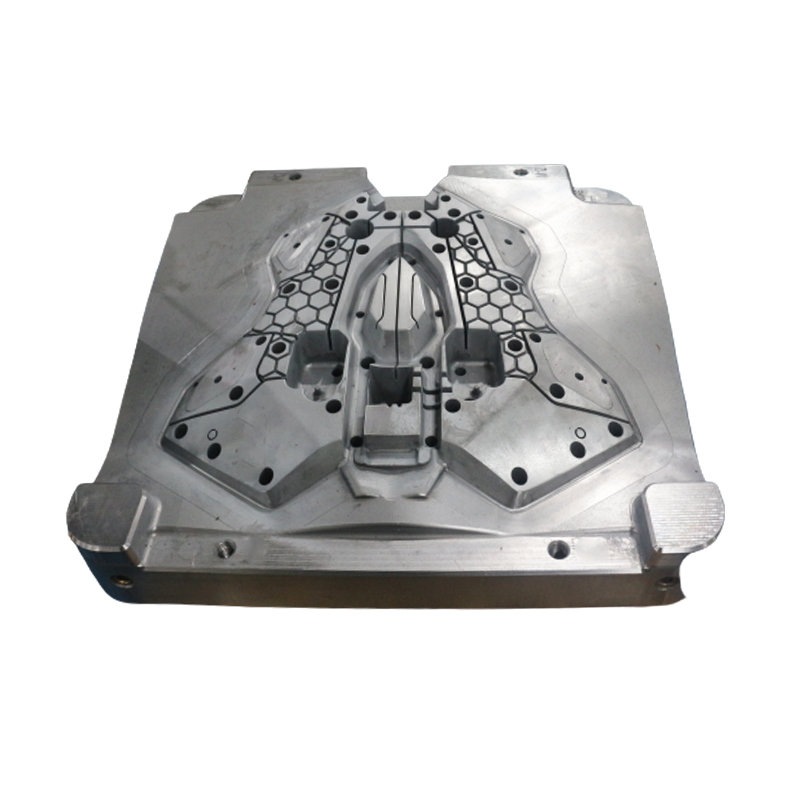

Mould Mold Tool Insert Manufacture

Product origin China

Delivery time as customer requested

Supply capacity as customer requested

Part name: Spare parts jigs and fixtures

Material: P20 (1.2311), H13 (1.2344), S7 (1.2357), 420 (1.2083), NAK80 (P21), S136 (1.2083)

Mould type: components, QTY as customer requested

Mould standard: LKM

Tolerance 0.05mm

Charactristic: Enhanced Precision, Increased Efficiency, Improved Durability, Effective Heat Dissipation, Streamlined Assembly, Improved Inspection, Increased Productivity

The advantages of manufacturing mold and die inserts are as follows:

1. Enhanced precision: Mold and die inserts are manufactured with high precision using advanced machining techniques. This ensures that the final product has a high level of accuracy and dimensional stability.

2. Cost-effective: By manufacturing mold and die inserts separately, it becomes possible to replace only the worn-out or damaged inserts instead of replacing the entire mold or die. This significantly reduces the cost of maintenance and increases the overall lifespan of the tooling.

3. Flexibility: Separate inserts allow for easy customization and modification of the mold or die. Different materials and designs can be used for inserts to accommodate various production requirements. This flexibility enables manufacturers to adapt to changing customer demands and produce a wide range of products.

4. Improved productivity: Mold and die inserts are designed to optimize the production process. They can be easily replaced, reducing downtime and increasing the efficiency of the manufacturing process. Additionally, inserts can be designed to enhance cooling or heating capabilities, improving cycle times and overall productivity.

5. Reduced lead time: Manufacturing mold and die inserts separately allows for faster production and delivery. Inserts can be produced in advance and stocked, reducing lead time for future tooling requirements. This enables manufacturers to respond quickly to customer orders and reduce overall production time.

6. Increased durability: Inserts can be manufactured from high-quality materials that are specifically chosen for their durability and wear resistance. This ensures that the mold or die can withstand the demanding conditions of production, resulting in a longer lifespan and reduced maintenance requirements.

Overall, the manufacturing of mold and die inserts offers numerous advantages such as enhanced precision, cost-effectiveness, flexibility, improved productivity, reduced lead time, and increased durability. These benefits contribute to the overall efficiency and success of the manufacturing process.