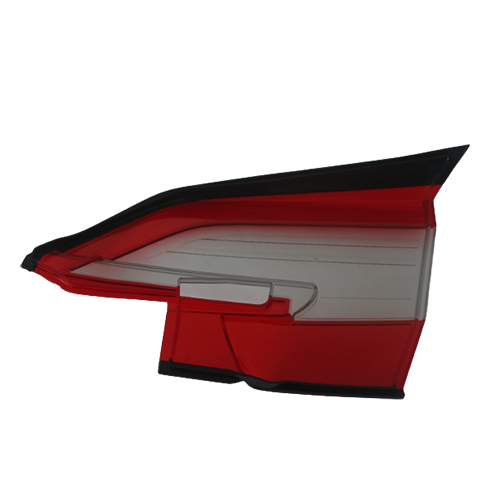

Plastic automotive light case

Product origin China

Delivery time as customer requested

Supply capacity 100,000pcs/month

Part name: Plastic automotive light case

Material: ABS+PC, PC, etc.

Mould type: 1 or 2 Cavity numbers

Cavity&Core: ASSAB136 or customized

Mould base: LKM

hot runner: needle nozzle or tunnel gate

Tolerance 0.05mm

Charactristic: Cost-effective, Easy maintainted and replaced, Versatile, Excellent formable

1.Durability: Plastic automotive lamps are made from high-quality materials that are resistant to impact, UV rays, and harsh weather conditions. This ensures that the lamps can withstand the rigors of everyday use and maintain their functionality and appearance for a long time.

2.Energy efficiency: Plastic automotive lamps are designed to be energy-efficient, consuming less power compared to traditional lamps. This not only helps to reduce fuel consumption but also contributes to environmental sustainability.

3.Design versatility: Plastic allows for greater design flexibility compared to other materials. Automotive lamp manufacturers can create intricate and stylish designs that enhance the overall aesthetics of the vehicle. This versatility also allows for the integration of various lighting technologies, such as LED and HID, to provide optimal visibility and safety on the road.

4.Easy installation: Plastic automotive lamps are designed for easy installation, making it convenient for both manufacturers and consumers. The lamps are lightweight, reducing the overall weight of the vehicle, and they come with standardized connectors and mounting points for hassle-free installation.

5.Cost-effectiveness: Plastic automotive lamps are generally more cost-effective compared to lamps made from other materials, such as glass or metal. The manufacturing process for plastic lamps is efficient and requires fewer resources, resulting in lower production costs. This cost-effectiveness translates to more affordable prices for consumers.

6.Safety: Plastic automotive lamps undergo rigorous testing to ensure compliance with safety standards. They are designed to provide optimal visibility for drivers, ensuring safe driving conditions during both day and night. Additionally, plastic lamps are less prone to shattering or breaking, reducing the risk of injury in the event of an accident.

7. Customization options: Plastic automotive lamps can be easily customized to meet specific requirements and preferences. Manufacturers can produce lamps in various shapes, sizes, and colors to match the design and branding of different vehicle models. This allows for greater personalization and differentiation in the automotive industry.