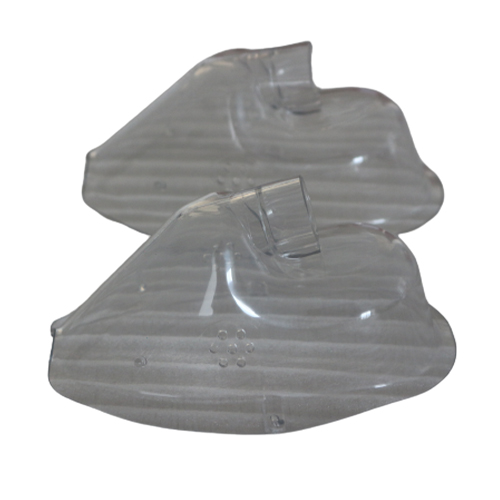

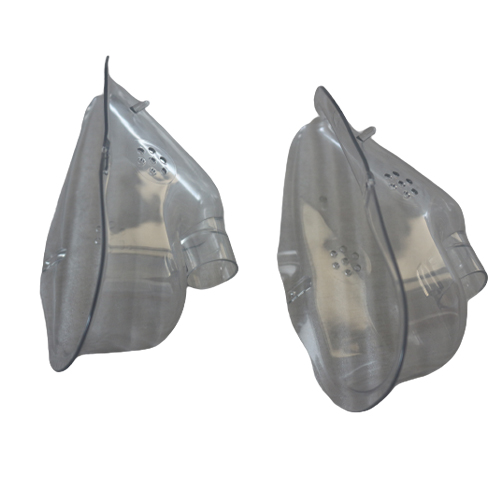

Plastic injected medical mask

Product origin China

Delivery time as customer requested

Supply capacity 100,000pcs/month

Part name: Plastic injected medical mask

Material: ABS+PC, PC, PA6+30%GF, etc.

Mould type: 1 or 2 Cavity numbers

Cavity&Core: 1.2344,1.2767, Superplast 400, or customized

Mould base: LKM

Hot runner: needle nozzle direct on part, hot tip, etc.

Cold runner:tunnel gate

Tolerance 0.05mm

Charactristic: Cost-effective, Easy maintainted and replaced, Versatile, Excellent formable

There are several advantages of using plastic injection medical face masks:

1. Lightweight: Plastic injection medical face masks are lightweight, making them comfortable to wear for extended periods. This is especially important for healthcare professionals who need to wear masks for long shifts.

2. Durability: These masks are made from high-quality plastic materials that are resistant to wear and tear. They can withstand repeated use and are less likely to break or develop cracks, ensuring their long-term durability.

3. Easy to clean: Plastic injection medical face masks can be easily cleaned and disinfected, making them suitable for reuse. They can be wiped down with sanitizing solutions or washed with soap and water, reducing the risk of contamination.

4. Customizable design: Plastic injection molding allows for the production of medical face masks in various shapes and sizes, catering to different facial structures and preferences. This ensures a better fit and improved comfort for the wearer.

5. Effective filtration: These masks are designed with multiple layers of filtration material, effectively preventing the transmission of airborne particles, droplets, and pathogens. They provide a high level of protection for both the wearer and those around them.

6. Cost-effective: Plastic injection molding is a cost-effective manufacturing process, allowing for the mass production of medical face masks at a lower cost per unit. This makes them more accessible and affordable for healthcare facilities and individuals.

7. Eco-friendly: Many plastic injection medical face masks are made from recyclable materials, reducing their environmental impact. Additionally, their reusable nature helps minimize waste generated from disposable masks.

Overall, plastic injection medical face masks offer several advantages such as lightweight construction, durability, easy cleaning, customizable design, effective filtration, cost-effectiveness, and eco-friendliness.