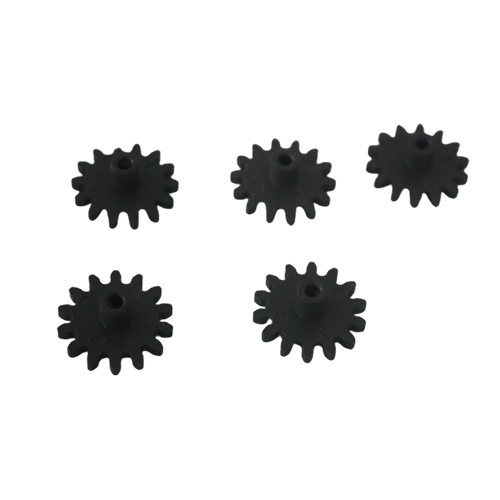

Printer ink sac

Product origin China

Delivery time as customer requested

Supply capacity 100,000pcs/month

Part name: Printer ink sac

Material: PP, PVC, ABS+PC, PC, PA6+30%GF, etc.

Mould type: 1 or 2 Cavity numbers, or customized

Cavity&Core: 1.2344,1.2767, Superplast 400, or customized

Mould base: LKM

Hot runner: needle nozzle direct on part, hot tip, etc.

Cold runner:tunnel gate

Tolerance 0.05mm

Charactristic: Cost-effective, Easy maintainted and replaced, Versatile, Excellent formable

The material used in printer ink sacs can vary depending on the specific printer model and brand. However, some common materials used in printer ink sacs include:

1. Rubber: Rubber is a common material used in ink sacs due to its flexibility and durability. It helps to create a seal between the ink cartridge and the printer, preventing leakage.

2. Silicone: Silicone is another material used in ink sacs due to its resistance to ink and its ability to maintain its shape and elasticity over time. It is often used in high-quality ink sacs that are designed for long-term use.

3. Plastic: Some ink sacs may be made of plastic materials, such as polyethylene or polypropylene. These materials are lightweight and can be molded into various shapes and sizes to fit different printer models.

4. Nylon: Nylon is a strong and durable material that is sometimes used in ink sacs. It helps to prevent ink leakage and provides stability to the ink cartridge.

5. Fabric: In some ink sacs, a fabric material may be used to reinforce the sac and provide additional strength. This can help to prevent tearing or puncturing of the sac.

It's important to note that the specific materials used in printer ink sacs can vary, and manufacturers may use different combinations of materials to achieve the desired performance and durability.