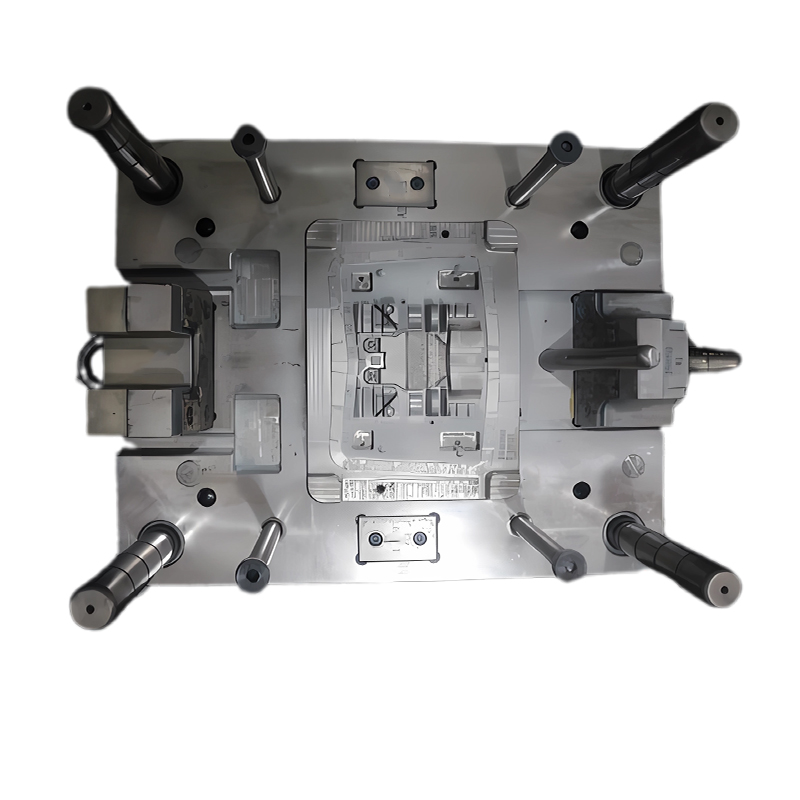

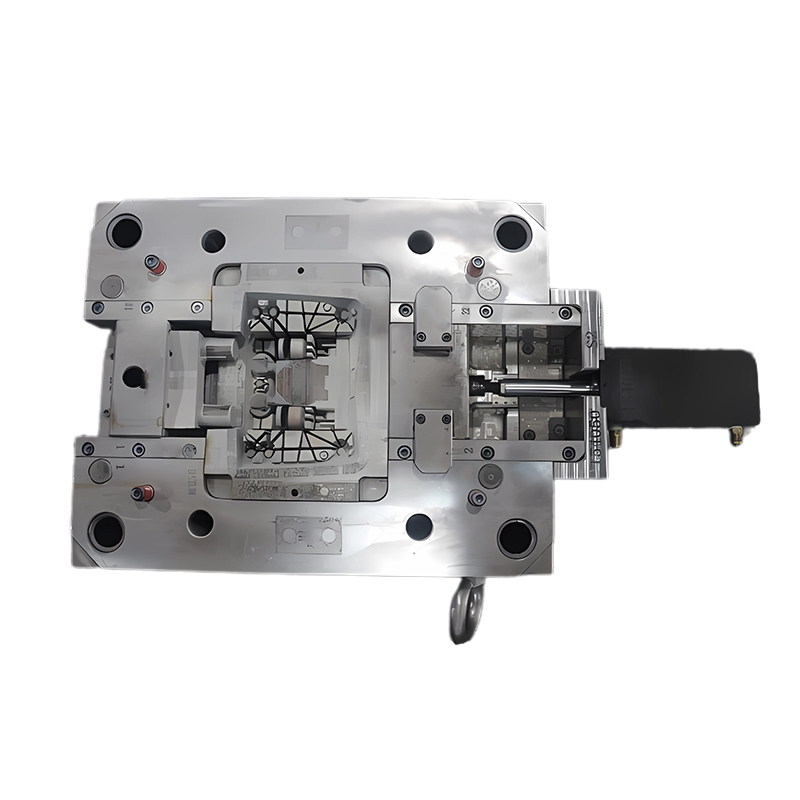

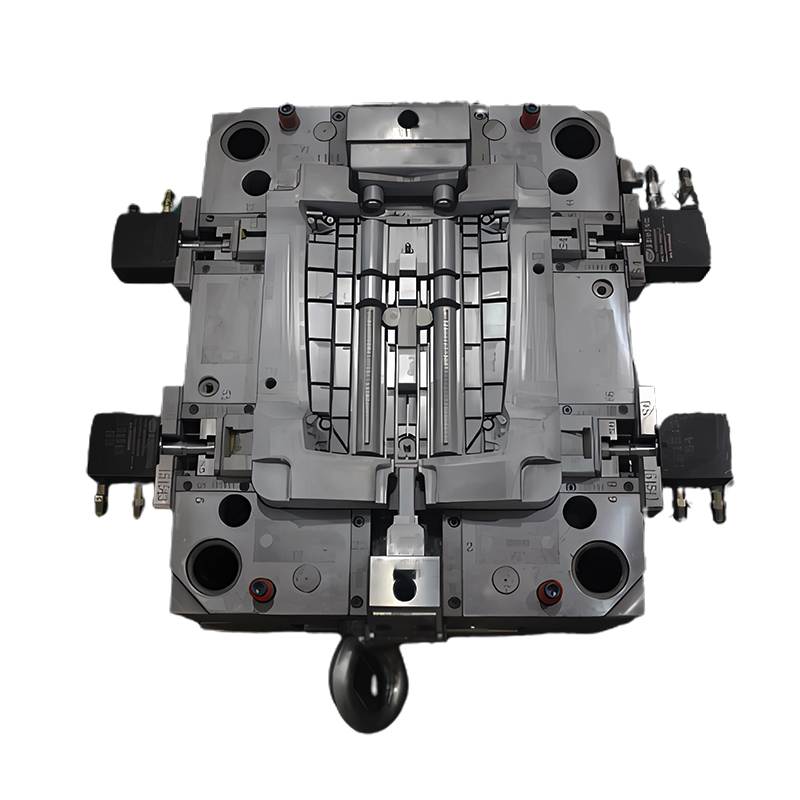

Medical Precision Plastic Injection Mold

Product origin China

Delivery time as customer requested

Supply capacity 20-40 sets/month

Part name: Medical Precision Plastic Injection Mold

Material: steel, 1.1730,1.2344,1.2767, Superplast 400, or customized , etc.

Mould type: 1 or 2 Cavity numbers or customized

Cavity&Core: P20, 718, NAK80, S136, H13, customized, etc.

Mould base: LKM

Hot runner: needle nozzle direct on part, hot tip, etc.

Cold runner:tunnel gate

Tolerance 0.05mm

Charactristic:

Repeatability- Make consistently good parts

Close-tolerance processing- precision is key in automotive parts

Secondary operations- all the processes you need under one roof

Scalability- the automotive industry is expected to grow

Wide material selection- ABS, PP, PVC, PC, PE, PA, POM, and more

The advantages of medical precision plastic injection molds are as follows:

1. High precision: Medical precision plastic injection molds are designed and manufactured with high precision, ensuring the accuracy and consistency of the final product. This is crucial in medical applications where even a slight deviation can have serious consequences.

2. Versatility: These molds can be customized to produce a wide range of medical devices and components, such as syringes, catheters, and surgical instruments. They can accommodate complex geometries and intricate designs, allowing for the production of highly specialized medical equipment.

3. Cost-effective production: Precision plastic injection molds enable high-volume production, resulting in cost savings due to economies of scale. The molds are durable and can withstand multiple cycles, minimizing the need for frequent replacements and reducing production costs in the long run.

4. Material compatibility: Medical precision plastic injection molds are designed to be compatible with a variety of medical-grade plastics, such as polycarbonate, polypropylene, and polyethylene. These materials are known for their biocompatibility, chemical resistance, and sterilization capabilities, making them suitable for medical applications.

5. Consistency and quality control: The use of precision plastic injection molds ensures consistent and repeatable production, minimizing variations in product quality. This is particularly important in medical settings where precision and reliability are critical for patient safety.

6. Enhanced functionality: Precision plastic injection molds can incorporate features such as overmolding, insert molding, and micro molding, allowing for the integration of multiple components and functionalities into a single device. This enhances the overall performance and usability of medical devices.

7. Rapid prototyping and development: Precision plastic injection molds enable rapid prototyping and iterative design improvements. This accelerates the product development cycle, allowing medical device manufacturers to bring new products to market faster.

Overall, medical precision plastic injection molds offer numerous advantages, including high precision, versatility, cost-effectiveness, material compatibility, consistency, quality control, enhanced functionality, and rapid prototyping capabilities. These advantages make them an essential tool in the production of medical devices and contribute to improving patient care and outcomes.