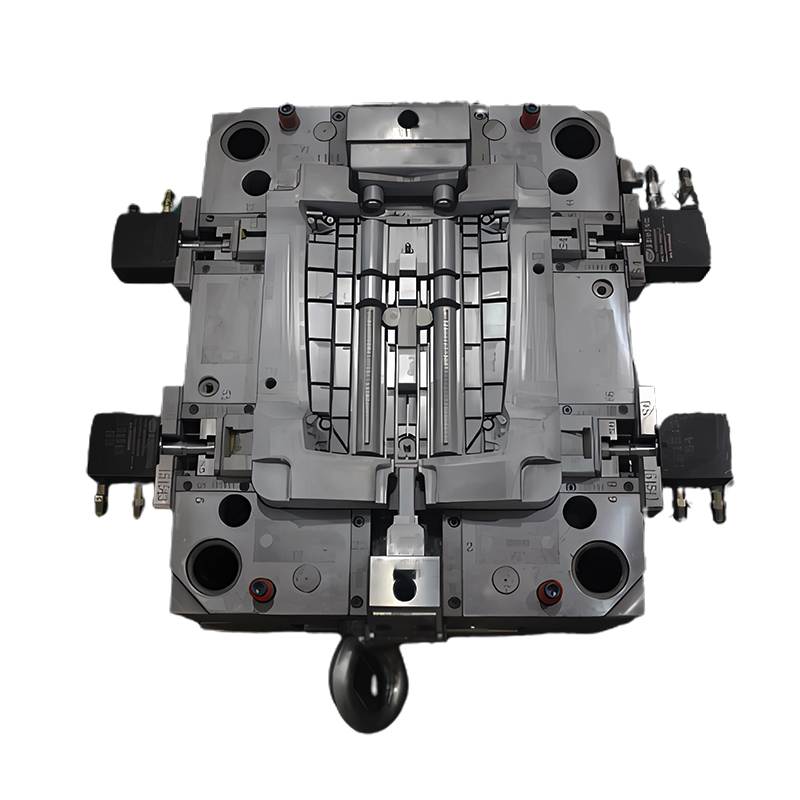

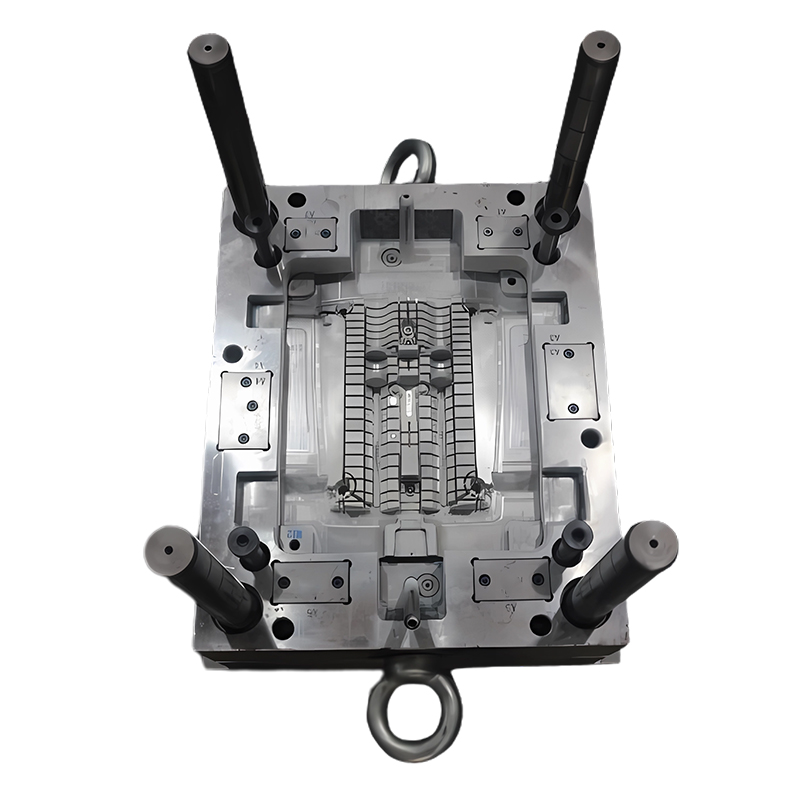

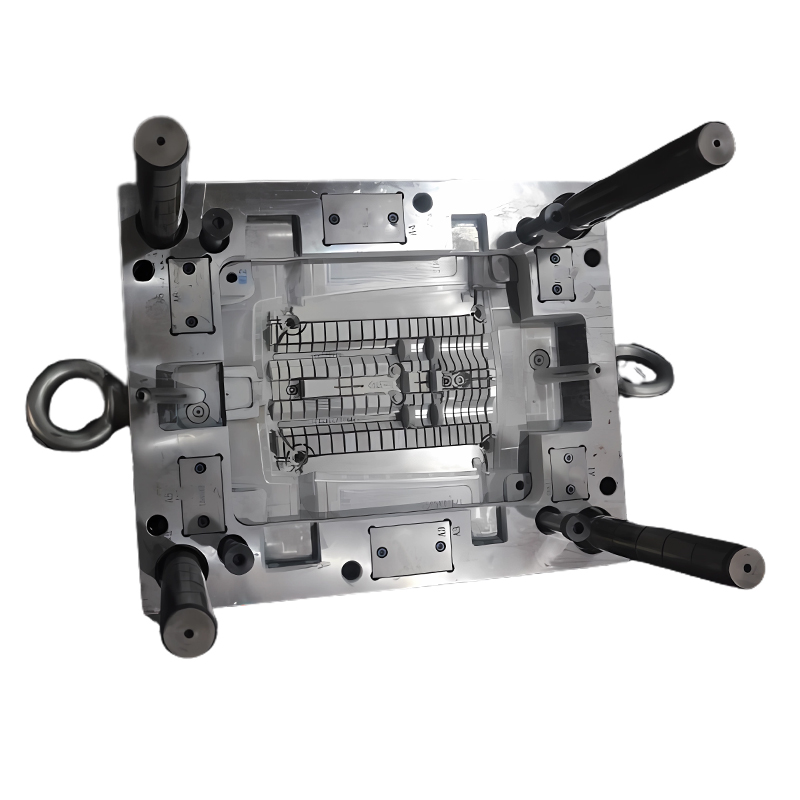

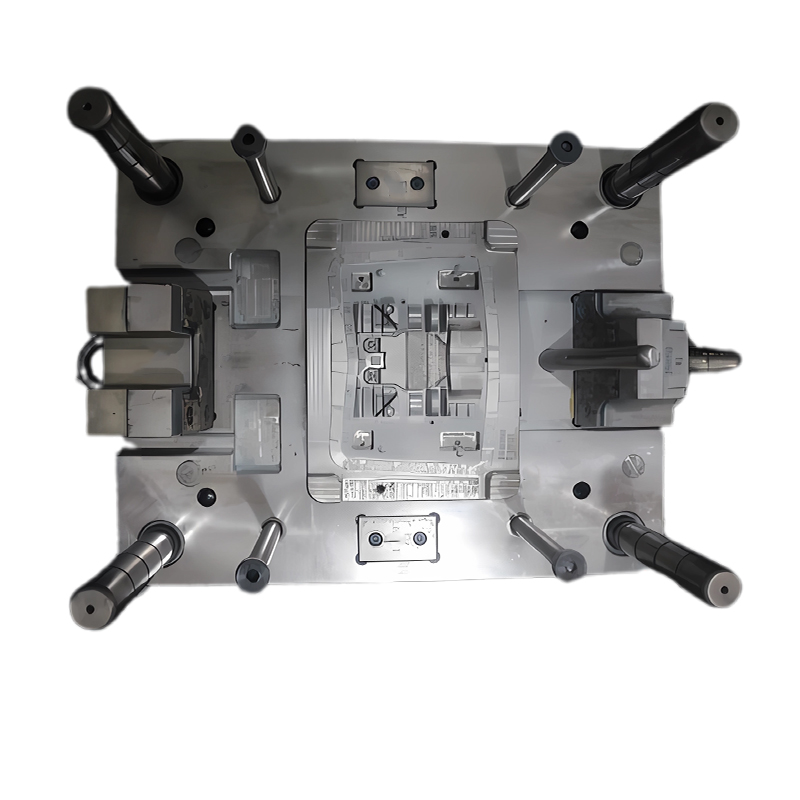

Medical Prototype Rapid Injection Mold

Product origin China

Delivery time as customer requested

Supply capacity 20-40 sets/month

Part name: Medical Prototype Rapid Injection Mold

Material: steel, P20 (1.2311), H13 (1.2344), S136 (1.2083), NAK80 (P21), 718 (1.2738), 420 (1.2083),420 (1.2083) etc.

Mould type: Prototype Rapid mold

Cavity&Core: steel, P20 (1.2311), H13 (1.2344), S136 (1.2083), NAK80 (P21), 718 (1.2738), 420 (1.2083),420 (1.2083) etc.

Mould base: LKM

Hot runner: needle nozzle direct on part, hot tip, etc.

Cold runner:tunnel gate

Tolerance: 0.05mm

Charactristic: Cost-effective, Design flexibility, material selection, Consistency and quality, Time and resource savings

There are several advantages of using a rapid injection model in healthcare:

1. Time-saving: The rapid injection model allows for quick and efficient administration of medications or vaccines. This reduces the overall time required for each injection, allowing healthcare professionals to treat more patients in a shorter amount of time.

2. Improved patient experience: With a rapid injection model, patients experience minimal discomfort during the injection process. The quick and efficient delivery of medication reduces the pain and anxiety associated with traditional injection methods, resulting in a more positive patient experience.

3. Accurate dosage delivery: The rapid injection model ensures precise and accurate dosage delivery. This is particularly important when administering medications that require specific dosage amounts to achieve optimal therapeutic effects. The model's design allows for consistent and reliable dosage administration, minimizing the risk of under or overdosing.

4. Reduced risk of needlestick injuries: The rapid injection model typically incorporates safety features, such as needle guards or retractable needles, which significantly reduce the risk of needlestick injuries for healthcare professionals. This helps to protect healthcare workers from potential bloodborne infections and promotes a safer working environment.

5. Cost-effective: The rapid injection model can be cost-effective in the long run. By reducing the time required for injections and minimizing the risk of complications, healthcare facilities can potentially save on labor costs, decrease the need for additional medical supplies, and improve overall operational efficiency.

Overall, the rapid injection model offers significant advantages in terms of time-saving, patient comfort, dosage accuracy, safety, and cost-effectiveness, making it a valuable tool in the healthcare industry.