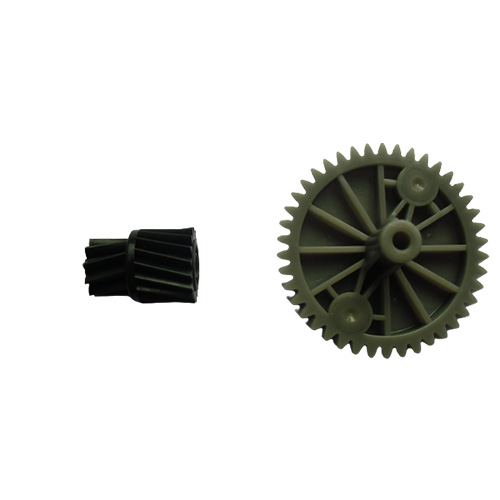

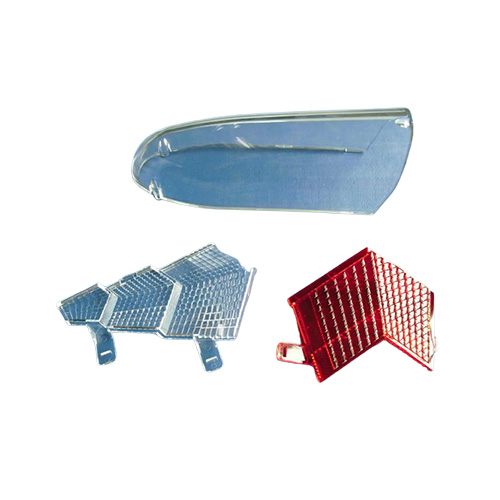

Plastic injected automotive gear parts

Product origin China

Delivery time as customer requested

Supply capacity 100,000pcs/month

Part name: Plastic injected automotive gear parts

Material: ABS+PC, PC, PA6+30%GF, etc.

Mould type: 1 or 2 Cavity numbers

Cavity&Core: 1.2344,1.2767, Superplast 400, or customized

Mould base: LKM

hot runner: needle nozzle direct on part,tunnel gate, hot tip

Tolerance 0.05mm

Charactristic: weight reduction, low noise and vibration, corrosion resistance, cost-effectiveness, design flexibility, self-lubricating properties, electrical insulation, and environmental sustainability.

There are several advantages of plastic automotive gear products:

1.Lightweight: Plastic gear products are significantly lighter than their metal counterparts, making them ideal for applications where weight reduction is crucial. This can contribute to improved fuel efficiency and overall vehicle performance.

2. Low noise and vibration: Plastic gears have excellent damping properties, which help reduce noise and vibration during operation. This results in a quieter and more comfortable driving experience for passengers.

3. Corrosion resistance: Plastic materials are inherently resistant to corrosion, making them suitable for use in environments where exposure to moisture, chemicals, or salt is common. This can extend the lifespan of the gear products and reduce maintenance costs.

4. Cost-effective: Plastic gear products are often more cost-effective than metal ones. The production process for plastic is generally less expensive, and the materials themselves are cheaper. This can result in significant cost savings for manufacturers and consumers.

5. Design flexibility: Plastic materials can be easily molded into complex shapes and sizes, allowing for greater design flexibility. This means that plastic gear products can be customized to meet specific requirements and fit seamlessly into various automotive applications.

6. Self-lubricating properties: Some plastic gear materials have self-lubricating properties, reducing the need for additional lubrication. This can simplify maintenance and reduce the risk of gear failure due to insufficient lubrication.

7. Electrical insulation: Plastic gear products can provide electrical insulation, making them suitable for use in electrical systems within vehicles. This can help prevent short circuits and improve overall safety.

8. Environmental sustainability: Plastic gear products can be made from recyclable materials, contributing to environmental sustainability efforts. Additionally, the lightweight nature of plastic can help reduce fuel consumption and carbon emissions during vehicle operation.

Overall, plastic automotive gear products offer numerous advantages, including weight reduction, low noise and vibration, corrosion resistance, cost-effectiveness, design flexibility, self-lubricating properties, electrical insulation, and environmental sustainability.