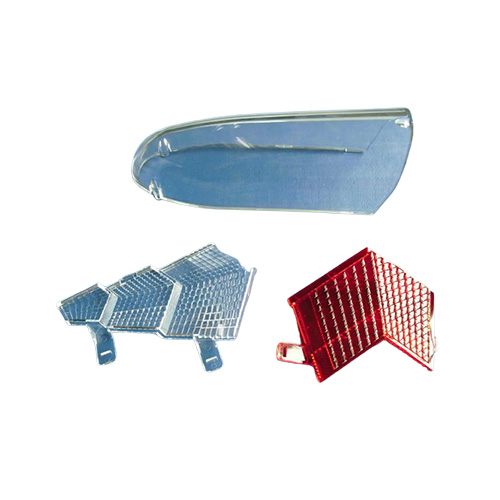

Plastic injection molded two shots part

Product origin China

Delivery time as customer requested

Supply capacity 100,000pcs/month

Part name: Plastic injection molded two shots part

Material: ABS+PC, PC, PA6+30%GF, etc.

Mould type: 1 or 2 Cavity numbers

Cavity&Core: 1.2344,1.2767, Superplast 400, or customized

Mould base: LKM

hot runner: needle nozzle direct on part,tunnel gate, hot tip

Tolerance 0.05mm

The advantages of plastic dual-color products are as follows:

1. Versatility: Plastic dual-color products can be produced in a wide range of shapes and sizes, making them suitable for various applications and industries. They can be customized to meet specific design requirements, allowing for greater flexibility in product development.

2. Aesthetic appeal: The use of dual-color injection molding technology enables the creation of visually appealing products with different colors and textures. This enhances the overall appearance of the product, making it more attractive to customers.

3. Improved functionality: Dual-color plastic products can be designed with different materials or properties in different areas, which enhances their functionality. For example, a product can have a soft-touch grip in one area and a rigid structure in another, providing a better user experience.

4. Cost-effective: Dual-color injection molding allows for the production of complex parts in a single operation, reducing the need for multiple manufacturing steps. This leads to cost savings in terms of production time, labor, and material usage.

5. Durability: Plastic dual-color products are often highly durable and resistant to wear, impact, and harsh environmental conditions. This makes them suitable for demanding applications where strength and longevity are important.

6. Brand differentiation: Dual-color products can help companies differentiate their products from competitors, as they offer unique visual and functional features. This can be an effective marketing tool to attract customers and build brand recognition.

7. Ease of assembly: Dual-color injection molding can simplify the assembly process by combining multiple components into a single piece. This reduces the number of parts, simplifies logistics, and improves overall product quality and reliability.

Overall, plastic dual-color products offer a combination of aesthetics, functionality, and cost-effectiveness, making them a popular choice in various industries.