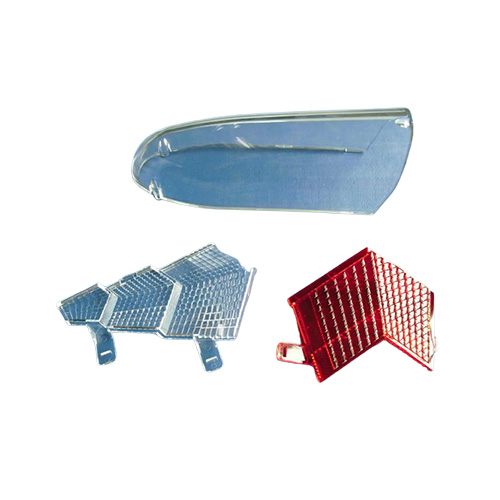

Gas assited automotive part

Product origin China

Delivery time as customer requested

Supply capacity 100,000pcs/month

Part name: Gas assited automotive part

Material: ABS+PC, PC, PA6+30%GF, etc.

Mould type: 1 or 2 Cavity numbers

Cavity&Core: 1.2344,1.2767, Superplast 400, or customized

Mould base: LKM

hot runner: needle nozzle direct on part,tunnel

Tolerance 0.05mm

Charactristic: Cost-effective, Easy maintainted and replaced, Versatile, Excellent formable

1. Lightweight: Plastic automotive components are much lighter than their metal counterparts, which helps to reduce the overall weight of the vehicle. This, in turn, improves fuel efficiency and reduces emissions.

2. Durability: Plastic automotive products are designed to be highly durable and long-lasting. They can withstand harsh weather conditions, extreme temperatures, and impacts without losing their structural integrity.

3. Corrosion resistance: Unlike metal components, plastic automotive products are not susceptible to rust or corrosion. This makes them ideal for use in areas with high humidity or exposure to saltwater.

4. Design flexibility: Plastic materials can be easily molded into complex shapes and designs, allowing for greater design flexibility in automotive applications. This enables manufacturers to create more aerodynamic and visually appealing vehicles.

5. Noise and vibration reduction: Plastic components have excellent noise and vibration dampening properties, which helps to improve the overall comfort and ride quality of the vehicle.

6. Cost-effective: Plastic automotive products are generally more cost-effective to manufacture than their metal counterparts. This can result in cost savings for both manufacturers and consumers.

7. Recyclability: Many plastic automotive products can be recycled at the end of their life cycle, reducing the environmental impact and promoting sustainability.

8. Electrical insulation: Plastic materials are excellent electrical insulators, making them suitable for use in automotive electrical systems and components.

9. Resistance to chemicals: Plastic automotive products are resistant to a wide range of chemicals, including oils, fuels, and cleaning agents. This ensures their longevity and performance in various automotive applications.

10. Easy maintenance: Plastic automotive products are typically easy to clean and maintain. They do not require regular painting or polishing, saving time and effort in vehicle upkeep.